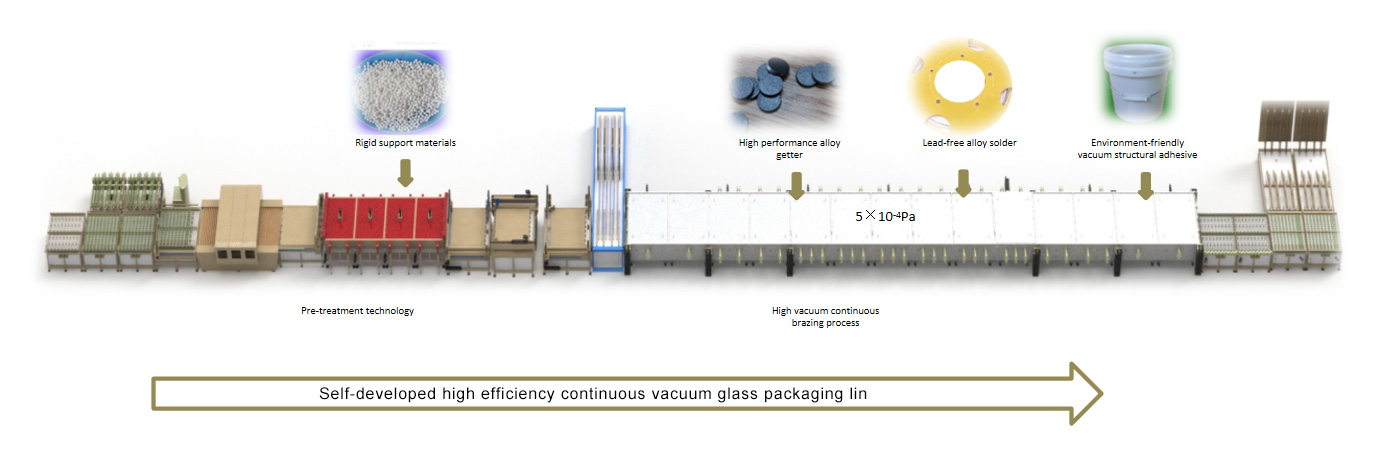

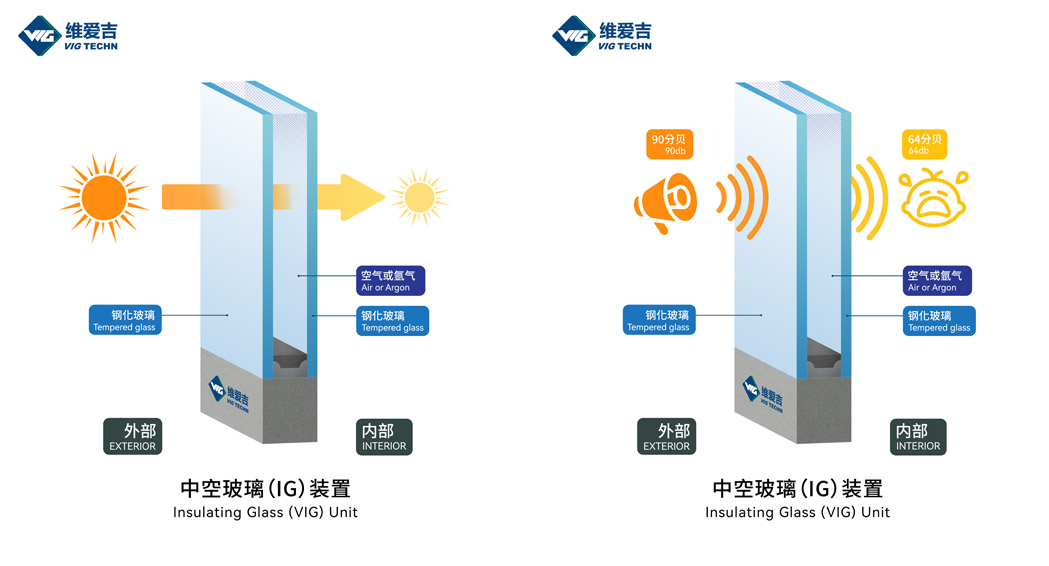

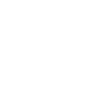

The main body consists of two pieces of glass stacked in parallel, in which supporting materials are placed at a certain distance. Welding materials are used around the glass for permanent sealing in a high vacuum environment. Polymer sealing materials are used around the core welding materials for structural strengthening and solder protection. High vacuum performance double sealed vacuum glass without air extraction port is obtained to meet the characteristics of heat insulation and sound insulation.

In order to improve heat insulation and adjust lighting performance, one piece of Low-E (low emissivity) coated glass would be used.

In order to balance the influence of gas penetration of glass itself and weld gas penetration on the service life of vacuum glass, alloy getter would be implanted in the vacuum chamber.

Vacuum leakage rate ≤10-12mbar.L/s, long life pursuit;

-50℃-100℃ use span, excellent environmental adaptability;

Using lead-free alloy solder with independent intellectual property rights, better fit with glass.

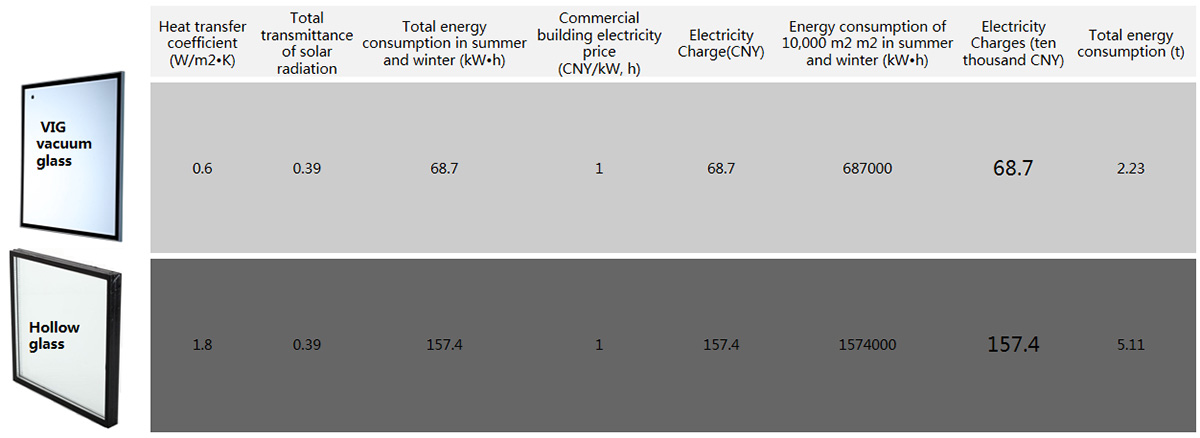

The heat insulation performance of VIG vacuum glass is improved by 2-4 times than that of insulating glass;

VIG vacuum glass can save 56.3% energy than ordinary insulating glass.

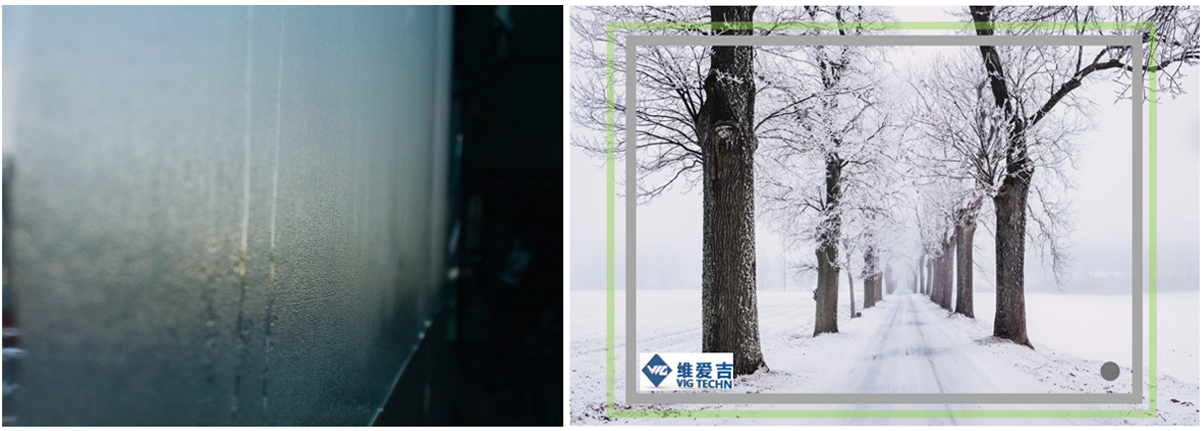

Dew point temperature is well below -60℃, excellent frost resistance

VIG vacuum glass sealing is adopted self-owned intellectual property rights of double-path sealing technology. The inner layer is sealed with independent low temperature lead-free solder, and the outer layer is made of polymer materials to strengthen the structure and protect the inner layer. Combined with a variety of cutting-edge heating technology, the continuous sealing in high vacuum environment is realized, and the strength property of tempered glass is completely maintained, so as to achieve the comprehensive guarantee of environmental protection, performance, efficiency, safety and other product indicators. The product can adapt to a variety of application scenarios.

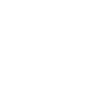

Fully tempered vacuum glass has excellent thermal insulation, sound insulation and noise reduction, light and transparent, safety and stability, and the vacuum leakage rate of VIG vacuum glass weld can reach 10 - ¹² Mbar.l/s to ensure the super long service life of vacuum glass and enjoy the quality life of green and energy saving in the construction field.

Fully tempered vacuum glass has excellent sound insulation and noise reduction, Frost / dew resistance and transparent lighting field of vision. It is an excellent choice for vehicle window glass materials. Scope of application: it is used for plane window on vehicles such as automobiles, high-speed rail motor cars, aircraft, cruise ships and so on.

Fully tempered vacuum glass has the advantages of energy saving, light weight, safety and no condensation, which promotes the quality upgrading in the field of household appliances. Scope of application: especially suitable for freezer, wine cabinet and display cabinet. Development Prospect: the cabinet door made of traditional glass has obvious disadvantages such as high energy consumption, poor thermal insulation effect and obvious condensation phenomenon.

Fully tempered vacuum glass has excellent heat insulation performance, excellent light transmittance and corrosion resistance, which promotes the progress and rapid development of new agriculture. Scope of application: all kinds of planting and breeding glass greenhouses in modern agriculture.

Fully tempered vacuum glass has the performance advantages of thermal insulation and constant inclination, making it the best lining glass in the field of building solar power generation. Scope of application: solar photovoltaic building, which is used as the substrate of solar panels in the integration of photovoltaic buildings to realize zero to negative energy consumption of buildings.