Fujian SuperTech’s vacuum insulation technology to provide efficient energy-saving solutions for various industries. We are able to offer different types of insulation materials with customized solutions to meet your specific needs.

Our customized products can help customers from various application fields to differentiate their products and enhance their market competitiveness. Customizable thermal conductivity, temperature, materials, sizes, and thicknesses to meet the specific needs of your industry and ensure that the products meet your project requirements, take your costs effectiveness into account to make the products and projects more energy-efficient and environmentally friendly.

Home Appliances: We have more than 17 years of experience in cooperation with the global leading refrigerator and freezer manufacturers such as Samsung, Whirlpool, Toshiba, LG, Siemens, Haier, Bosch, Arcelik, etc., and provide customized vacuum insulation panel for them. According to manufacturer's different performance requirements (mainly thermal conductivity), size, thickness, and material requirements to maximize the internal space of the product while achieving the best thermal insulation effect. Our parts help to save electricity and enables the product to reach the EU A-level energy efficiency standard significantly.

Electric Vehicles: Through vacuum insulation technology, select different performance parameters, different thermal conductivity, different materials and thicknesses of vacuum insulation panels, effectively extend the driving range and improve energy efficiency, can create different prices, differentiated electric vehicle products, improve market competitiveness;

Water Heater Tank: vacuum insulation technology help to achieve more energy-efficient heating. At the same time, after the shape and cut angle, the vacuum insulation panel fitted to the heat insulation location, can meet customers’ needs.

Pipeline: For reduce heat loss, improve energy efficiency, and reduce energy costs. In particular, for energy transmission protection in LNG pipelines, we offer customized solutions.

Building: To provide more environmentally friendly, more energy efficient low-energy building solutions for your self-health and comfort. You can put forward different insulation requirements for external and internal walls of building, such as customizing different materials and different thickness of thermal insulation materials to improve the area utilization rate, reduce the space occupation of thermal insulation layer as much as possible. You can also choose our vacuum glass, which can provide energy saving, power saving and cost reduction, and have a clear vision, enjoy quality life.

Refrigerated Transport: to ensure the continuity of cold chain transport, and ensure the safety and effectiveness of food and medicine. You can customize vacuum insulated box according to different distances, different holding times, and different temperature control requirements.

Medicine and Biotechnology: precise temperature control to ensure the stability and effectiveness of drugs and biological samples.

Food Industry: Use environmentally friendly vacuum insulation panel to extend food shelf life, reduce food waste, reduce energy consumption and improve efficiency.

Cold Chain Logistics: reliable insulation technology to ensure the safety and effectiveness of food and drugs.

Aerospace and Aviation: Efficient thermal insulation technology to ensure the stable operation of spacecraft and aircraft thermal control systems.

Low Temperature Technology: reduce energy consumption, improve efficiency, and provide reliable heat insulation protection for low temperature equipment.

①Vacuum Insulation Panel (VIP): Customize the insulation needs of various shapes, sizes, thicknesses and performance, such as household appliances, steam ovens, new energy automobile parts, building insulation, pipeline insulation, etc.

②Vacuum Insulated Box: suitable for transportation and storage of temperature-sensitive items, you can customize different temperature control range, different holding time, such as medicine, food, biological samples, etc.

③Vacuum Glass: suitable for building insulation and energy saving, customized product of different lengths, widths and thicknesses; different U value (K value); Choose vacuum glass products containing two or three pieces of glass, such as Windows, glass curtain walls, home appliance visualization panels, wine cabinets, etc.

Performance (thermal conductivity): Customized according to different thermal conductivity requirements to meet your different needs for thermal insulation performance.

Vacuum insulation plate: Initial thermal conductivity: 1.5 ~ 5mW/(m·k) range optional.

Vacuum glass: heat transfer coefficient as low as 0.42(w/㎡·K)

You can customize the materials of vacuum insulation panel, such as the material of high-performance barrier film, the material of core material, different amounts of desiccant, getter, etc.

Coose Vacuum Insulated Box type: EPP-PU-VIP, Fumed Silica, Insulated Pallet Shipper, Folding or Integrated Insulated Box;

Choose Vacuum Glass: single or double silver plating, etc.;

①Film materials: Suitable film materials can be selected according to the application field, such as stainless-steel barrier film, aluminum film, plastic film, FPC isolation film, aluminum-plastic composite film, aluminum-free composite film, nano barrier film, polyester aluminum-coated film, coated silicon oxide film, battery diaphragm, aluminum-plastic film, etc., to meet your strength, corrosion resistance and aesthetic needs. Widely used in food packaging, pharmaceutical packaging, industrial packaging, electronic components packaging and different types of requirements of vacuum insulation panel and other fields, the output of more than 100,000,000 square meters/year, can match your mass purchase needs.

②Core material: Fujian SuperTech Vacuum Insulation Panels have a variety of core material and mass production technology. Have large production base, such as: annual output of 36,000 tons of ultra-fine glass fiber core material, and can mass produce a variety of Vacuum Insulation Panels core materials:

Fumed Silica Panel

Fiberglass Panel

Polyurethane Panel

Phenolic Foam Panel

If you have other needs, please contact us, we can provide technical research and development team support to match your needs also, and real-time video conferencing services.

③Desiccant and Getter:

Quality has reached the international leading level, the annual output more than 40,000,000 pieces/year, can match your mass purchase needs.

Size: Customize the suitable size according to your space and needs, then we can calculate the total square and save you money. This size includes different length, width and thickness requirements.

Shape: According to your special needs, we can customize vacuum insulation panels in various shapes, such as round or cylindrical, oval, arc, with cut angle, collapsible VIP, vacuum insulation panels with cutting openings, openings, irregular shapes, etc. Please refer to the following example photos:

By selecting different thermal insulation core materials and barrier types, using vacuum insulation technology, it is possible to challenge the usage scenario of minimum temperatures of -196 ° C and maximum temperatures of +800° C.

You can also customize different vacuum insulation solutions according to the insulation temperature requirements and usage scenarios that you need. It is still expanding its range of low-temperature and thermostatic transport solutions, introducing new transport boxes that provide both cold and heat preservation, which can be customized according to your needs.

Color: Especially vacuum insulated boxes, insulated bags, you can choose the color you like, or customize the color according to your brand image.

Logo: Our vacuum incubator can be customized according to your needs, you can add the company logo or personalized picture on the product for you to enhance the brand image.

Our professional team will provide you with customized services, from consulting, design, production to shipping, to ensure that you are satisfied with services and products.

①Vacuum insulation technology leading: As a leader in the field of vacuum insulation in China, Fujian SuperTech Advanced Material has more than 17 years of research and development and production experience, Fujian Longyan factory has an annual output of 12 million square meters of vacuum insulation panel, Anhui Hefei factory annual output is increasing. We are cooperating with the world's home appliances leaders, meet their requirements on production capacity, quality, delivery, and continue to lead the development of the industry, keep innovating, to provide customers with the most competitive thermal insulation solutions.

②Complete Industry Chain: Fujian SuperTech becomes one of the few enterprises in the industry with the integrated production capacity of vacuum insulation panel core material production, barrier film composite and bag production, adsorption material production, vacuum packaging and product performance testing equipment, and master the complete production chain of vacuum insulation panel. Over the past 17 years, through technological improvement, breakthroughs, and transformation, we have built an integrated capability in the field of vacuum insulation, built a strong technical barrier and market position, and made Fujian SuperTech Advanced Material gain a leading position in the industry.

③Comprehensive VIP Types: We offer a wide range of vacuum insulated panels (VIP), including different core materials (fumed silica, glass fiber, polyurethane) and a variety of shapes, thickness sizes, and thermal conductivity to meet the needs and applications of our customers.

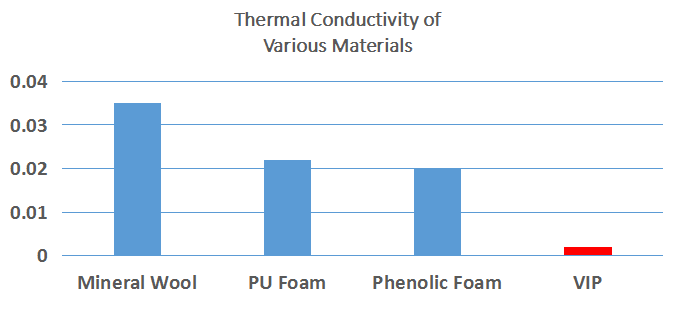

④Excellent Thermal Insulation Performance: With an annual output of 36,000 tons of ultra-fine glass fiber core material and the initial thermal conductivity is less than 1.5mW/(m.K). Our VIP products have extremely high thermal insulation performance, which can effectively reduce heat loss, improve energy efficiency, and save energy costs for customers.

⑤Space Saving: Compared to traditional insulation materials, VIP's thinner thickness can save space, making it ideal for applications with limited space.

⑥Customized Services: We provide customized services, design and manufacture VIP products according to the specific needs of our customers to ensure the best insulation effect.

⑦High Quality Assurance: We have a large number of unique patents (122 patents as of October 2024), comprehensive quality assurance system to ensure that each VIP product quality and performance to the highest standards.

⑧Sustainable Development: Our VIP products have environmentally friendly features that reduce energy consumption and contribute to the environment.

⑨Professional Technical Support: We provide professional technical support to help customers select the right VIP products and solve any technical problems.

Choose Fujian SuperTech Advanced Material.

Choose reliable quality, innovative technology and excellent service.

Contact us for your customized solution!